To increase the life time of the CNC-machine.

Velum protective filter has been designed and realised to protect electric and electronic machines in industrial production plants from dust and oily mist. For their well-functioning and best productivity,

all automations, robots and numerical control machines need constant maintenance operations and a regular filter replacement. Urgent deadlines that do not allow downtime, the lack of specialised manpower or even simple omissions may prevent companies from replacing filters regularly.

Velum protective filter is applied externally, directly to the entrance grid of ventilation and cooling

systems of the production unit: once applied, Velum gathers and holds dust and oily mist in its patented-knitted fabric and ensures, while protecting the inner filter, the normal passage of fresh and clean air in the machine. To ensure the best production efficiency for your machines, replace Velum once a week.

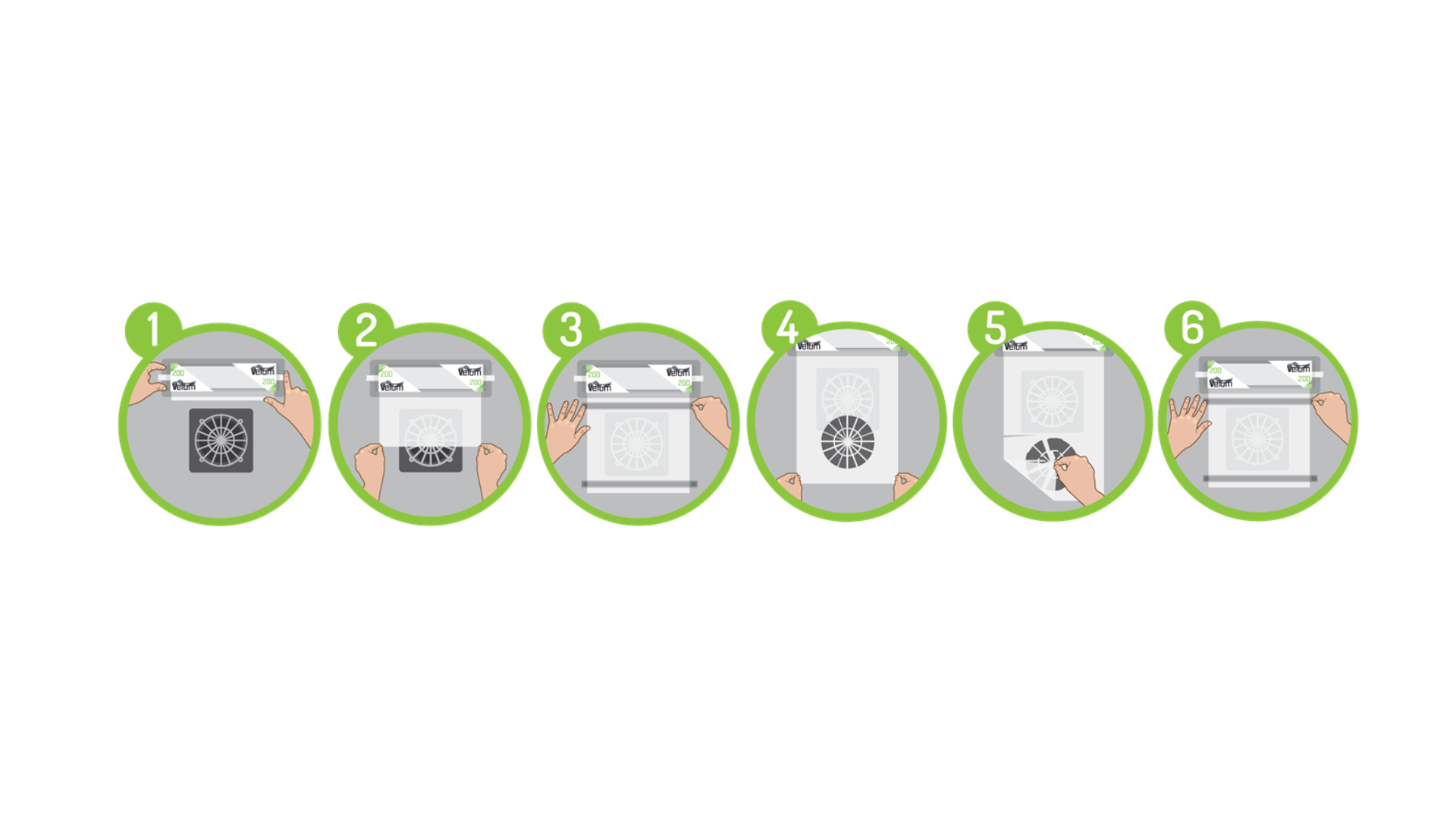

The Velum replacement check is purely visual: when the Velum protective filter is covered by polluting agents, you need to replace it. The replacement takes place in 5 seconds and you do not need any specialised manpower, thus avoiding downtimes and cutting down maintenance costs and any missed production costs that may be due to the inner filter replacement.

Velum is easy to apply and allows to efficiently plan the protection of any industrial machine:

you just need to write down in the appropriate space the date of your last replacement and the name of the operator who has done it, so to avoid omissions, downtimes or breakdowns due to the missed replacement of the inner filter.

Available in 5 sizes:

600 mm – 500 mm – 400 mm – 300 mm – 200 mm

Each roll includes 110 filters.